Web Thermometer Pt100/Pt1000 Solutions

Advanced Environmental Control with Web Thermometer Pt100/Pt1000

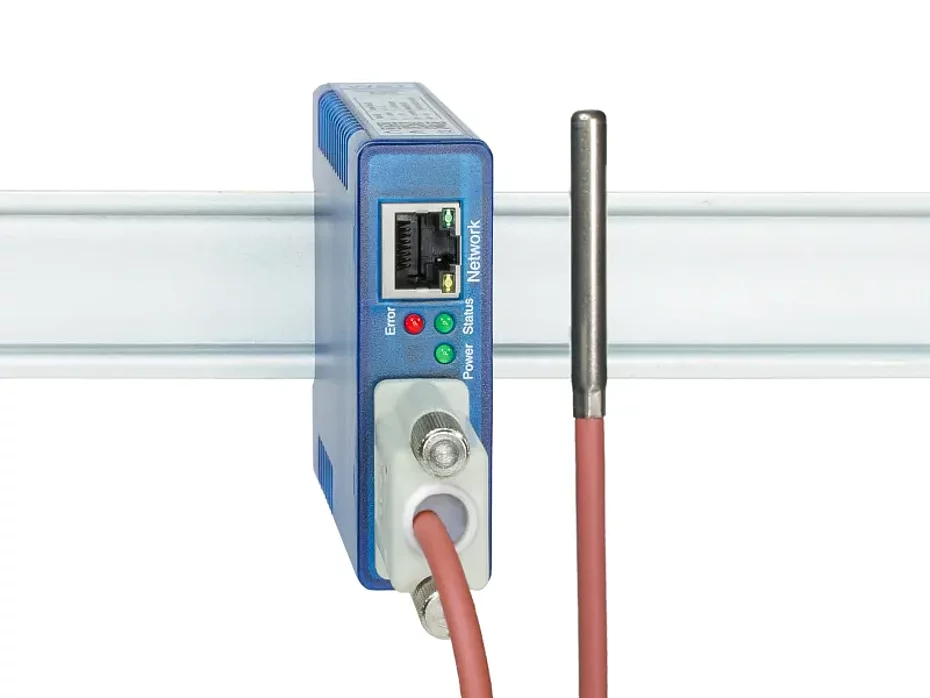

In an age where seamless connectivity and digital precision drive operational success, ensuring accurate oversight of environmental conditions is paramount across data centers, offices, and manufacturing facilities. The Web Thermometer Pt100/Pt1000, crafted by a renowned innovator, delivers a cutting-edge solution for temperature measurement and data management, characterized by adaptability, dependability, and effortless integration into existing infrastructures. Equipped with sophisticated sensor technology and robust network functionalities, this device excels in IT environments, Industry 4.0 settings, and more. This article explores its technical capabilities, diverse use cases, and the significant advantages it offers for modern temperature monitoring systems.

At the heart of this device lies a high-precision Pt100 sensor, included with the unit, which accurately measures temperatures from -50 degrees Celsius to +180 degrees Celsius. For specialized needs, its input extends support to a range of -200 degrees Celsius to +650 degrees Celsius, making it a versatile tool for varied settings. The compatibility with both Pt100 and Pt1000 sensors ensures exceptional accuracy and stability, ideal for critical applications like industrial processes or server room monitoring. This precision is vital for preventing equipment failures, optimizing energy consumption, and minimizing operational costs in environments requiring stringent temperature control.

The Web Thermometer’s intuitive design simplifies operation through a browser-based interface, eliminating the need for additional software. Users can access live temperature data, analyze historical trends, and fine-tune settings with ease. Graphical visualizations of temperature fluctuations enable quick identification of patterns or potential issues, enhancing proactive management. This accessibility makes the device suitable for both experienced technicians and those new to environmental sensors, ensuring seamless integration into diverse network frameworks for efficient humidity monitoring and temperature oversight.

- The device offers robust alerting capabilities, allowing up to 12 customizable notifications for temperature threshold violations, delivered via email, SNMP traps, or Syslog. This is critical in high-stakes environments like server rooms, where rapid response to anomalies prevents costly disruptions. Additionally, automated email reports provide regular summaries, supporting audits, energy optimization, and operational documentation, enhancing transparency in monitoring systems.

- Tailored for Industry 4.0 and IoT ecosystems, the thermometer supports protocols like OPC UA, REST, and MQTT, enabling smooth integration into automation platforms. Interfaces such as SNMPv1, SNMPv2c, SNMPv3, Modbus-TCP, OPC DA, and Sensobase facilitate database connectivity via ODBC. Developers can access data through TCP or UDP sockets for custom solutions, while HTTP access supports dynamic integration into websites via JavaScript (AJAX), making it a vital tool for networked temperature control.

- Data storage is comprehensive, with an integrated logger capturing records for up to 20 years, depending on intervals (15 seconds to 1 hour), with a minimum of 16 weeks. Data can be exported via FTP, Excel, or email attachments for flexible analysis. Cloud integration with the manufacturer’s platform ensures global access, ideal for remote teams or global operations. A battery-backed clock, synchronized with time servers, provides precise timestamps for accurate data logging in IoT sensors applications.

- The thermometer supports a wide array of applications, monitoring data centers to prevent overheating and extend hardware life. In offices, it optimizes HVAC systems, enhancing comfort and reducing energy costs. In industrial settings, it ensures process stability where precise temperature control is crucial. For Green IT, it provides data to improve cooling efficiency, minimizing environmental impact. Its network-driven design simplifies installation, expanding its utility in remote monitoring scenarios.

- Power flexibility is achieved via Power-over-Ethernet (PoE), supporting phantom and spare-pair powering, or an optional external adapter for non-PoE environments. Compliance with standards like EN 61000-6-2 for interference immunity and EN 55032:2015 + A1 Class B, EN 61000-3-2, and EN 61000-3-3 for low emissions ensures reliable performance in demanding conditions of industrial temperature control.

- Please note: No external power adapter is included with the device.

- Engineered for longevity, the device is built for continuous operation, backed by a five-year warranty. Its sturdy construction and DIN rail mounting option suit industrial environments. A battery-supported clock, enhanced by time server synchronization, ensures precise timekeeping, reinforcing reliability in environmental sensors applications.

- This thermometer is an essential asset for precise environmental oversight, offering a versatile solution for data centers, offices, and factories. With its Pt100/Pt1000 sensors, data logging, and IoT integration via protocols like MQTT, it meets Industry 4.0 demands. Whether for energy efficiency, data archiving, or equipment protection, it’s a critical tool for professionals in humidity monitoring and temperature control.

Integrating IP sensors like the Web Thermometer Pt100/Pt1000 into environmental monitoring systems enhances operational reliability. These devices deliver real-time data essential for maintaining optimal conditions in sensitive areas like server rooms, where minor shifts can lead to significant downtime. WiFi temperature sensors extend monitoring to remote locations, offering flexibility in deployment, which is invaluable in industrial settings requiring constant vigilance for performance and safety.

IoT temperature sensors streamline data aggregation by connecting to central hubs, providing a comprehensive environmental overview. This supports advanced analytics to predict trends or identify inefficiencies. In data centers, configurable alarms ensure rapid responses to deviations via notifications, safeguarding equipment. The precision of Pt100/Pt1000 sensors underpins the accuracy of these monitoring systems, making them a cornerstone of effective temperature and humidity management.

Remote temperature monitors have transformed climate control with protocols like MQTT, enabling efficient data transfer in low-bandwidth scenarios. Cloud-based monitoring offers global accessibility, allowing users to view dashboards, generate reports, or automate responses. In server room monitoring, this reduces response times and costs, as IT teams manage systems remotely. Data loggers preserve historical records, aiding compliance and audits, positioning the device as a leader in smart environmental control.

- Humidity sensors enhance temperature monitoring by preventing issues like condensation, providing a complete environmental picture for informed decisions.

- PoE simplifies installation, combining data and power in one cable, enhancing reliability in critical monitoring setups.

- Customizable alarms ensure relevant notifications, maintaining user engagement in temperature control systems.

- Cloud integration supports scalable device management, streamlining operations for large networks in IoT sensors ecosystems.

- Industrial temperature control maintains safe process parameters, preventing damage to products or equipment.

- Data logging enables retrospective analysis, offering insights for system optimization and troubleshooting.

- Secure IoT sensors with encryption protect data integrity, ensuring compliance with regulations.

- Remote monitoring via mobile apps allows real-time status checks, ideal for multi-site management.

- WiFi temperature sensors require stable networks, supported by redundant connections to prevent data loss.

- Server room temperature monitoring demands high-resolution sensors to detect subtle changes, indicating potential issues.

- IP sensors integrate with smart building systems, automating HVAC adjustments for energy efficiency.

- Temperature monitoring in healthcare ensures proper storage conditions for sensitive materials.

- Flexible power options suit off-grid applications, expanding usability in remote monitoring.

- Cloud platforms with machine learning predict anomalies, enabling predictive maintenance for cost savings.

- The synergy of IP thermometers, humidity monitoring, and IoT integration creates a robust framework for future-ready control.

The Pt100/Pt1000 sensors’ linear resistance-temperature relationship ensures minimal calibration and long-term stability, reducing maintenance costs. In IP thermometer applications, they achieve resolutions as fine as 0.01 degrees Celsius, ideal for precise control. Paired with humidity sensors, they support dew point calculations, preventing moisture damage in electronics. These strengths make the device reliable for environmental sensors in demanding settings.

MQTT’s publish-subscribe model enhances scalability, allowing sensors to send data to brokers for multiple subscribers like dashboards or alerts, conserving bandwidth. Cloud platforms offer robust data processing and visualization, enabling deep insights. The Web Thermometer’s support for these protocols ensures seamless integration into IoT temperature sensors ecosystems, enhancing efficiency.

Effective deployment requires strategic sensor placement, avoiding heat sources or airflow blockages. Regular calibration maintains precision, while redundant sensors in server rooms ensure uninterrupted monitoring. PoE simplifies installations, supporting centralized power management. This comprehensive approach delivers reliable, efficient temperature and humidity monitoring for diverse industries.

- Digital environmental sensors enable advanced data handling, including wireless transmission and mobile app integration.

- Tiered alarm notifications allow graduated responses, from warnings to urgent alerts.

- PoE reduces installation costs, ideal for retrofitting buildings with modern monitoring capabilities.

- Variable data logging intervals balance detail and storage efficiency.

- Industrial temperature control leverages PID algorithms, adjusting based on sensor data.

- Secure data transmission via VPNs ensures compliance with regulations like GDPR.

- WiFi sensors benefit from mesh networks, extending coverage in large areas.

- Server room monitoring includes air quality, providing a holistic equipment health check.

- API access enables custom software, tailoring solutions to specific needs.

- Temperature monitoring in logistics tracks cold chains, ensuring product integrity.

- Open-source cloud platforms reduce costs, enabling small businesses to adopt advanced monitoring.

- Humidity sensors require periodic cleaning to maintain accuracy in harsh environments.

- IoT sensors with battery indicators prevent downtime by signaling replacement needs.

- Integration with building management systems automates lighting and ventilation.

- Quality IP thermometers ensure reduced risks, optimized operations, and prolonged asset lifespans.

Web thermometer Pt100 / Pt1000