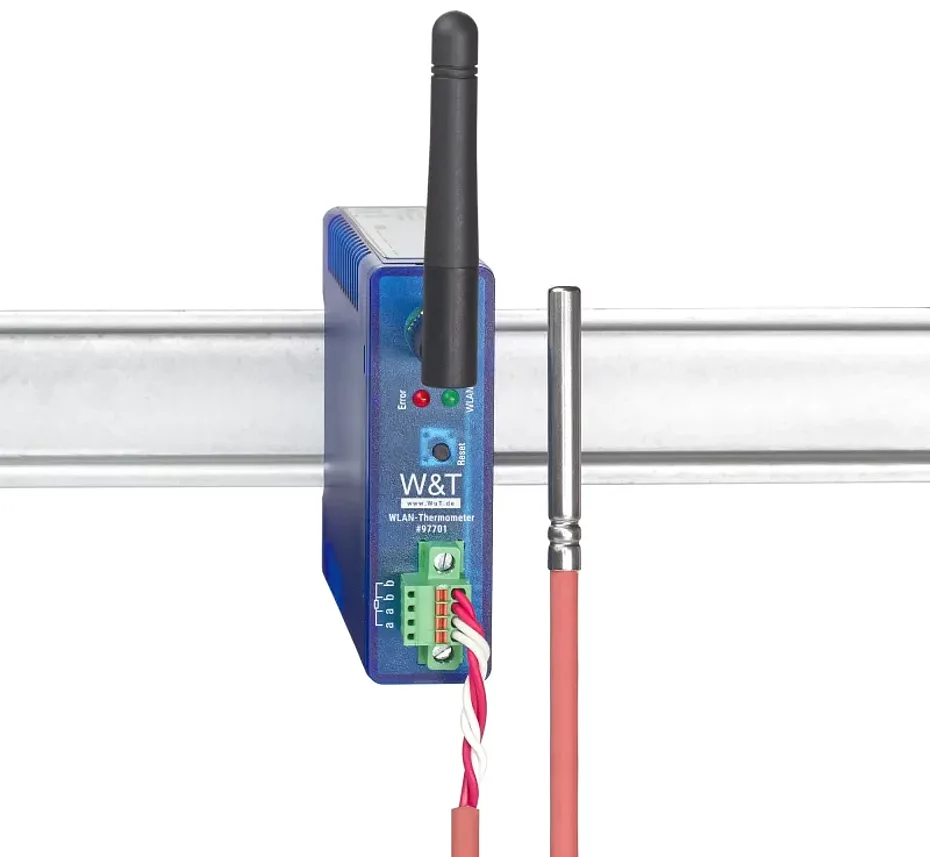

WLAN thermometer 1x Pt100

Flexible IP Temperature Monitoring with Advanced Sensors

In today's interconnected world, where networked technologies and real-time data transmission are becoming increasingly vital, accurate and adaptable oversight of environmental conditions is crucial. The IP thermometer equipped with a single Pt100 probe from a leading manufacturer provides a cutting-edge approach that captures temperature readings with exceptional precision and delivers them via a wireless local area network. By incorporating features like integration into cloud platforms, transmission of MQTT messages, and delivery of push alerts to mobile devices, this device is perfectly suited for contemporary information technology and manufacturing settings. This discussion examines the technical specifications, potential applications, and benefits of this sophisticated measurement tool that is transforming the landscape of environmental surveillance.

Accurate readings are achieved through the use of a premium Pt100 temperature sensor, which detects values ranging from -50 degrees Celsius to +180 degrees Celsius. The input supports an expanded scope from -200 degrees Celsius to +650 degrees Celsius, making it appropriate for demanding scenarios in data centers, production lines, or office spaces. The Pt100 element is renowned for its superior accuracy and reliability, supplying exact data essential for preventing equipment failures, enhancing energy usage, and reducing operational expenses. This durable sensor technology positions the device as a dependable option for expert users in various fields.

A standout attribute of this IP thermometer is its versatile connectivity options through wireless networks, operable in both access point and client configurations. This facilitates seamless incorporation into existing infrastructures or the creation of dedicated networks for data collection. The user-friendly interface allows straightforward setup without needing extra programs. Individuals can access live temperature information via web browsers, review historical trends, and modify parameters. Visual representations of changes over time aid in spotting patterns and possible issues. Such ease of use makes it suitable for seasoned administrators as well as newcomers in the domain of temperature monitoring systems.

- The IP thermometer offers sophisticated alerting and notification capabilities, supporting MQTT protocols for effortless merging with Internet of Things ecosystems, along with push notifications via services like ntfy.sh that can be sent straight to smartphones. These features prove invaluable in high-stakes areas such as server rooms where prompt responses to deviations are necessary. An activation key for accessing the manufacturer's cloud service comes included, simplifying the utilization of online functionalities. Such alerting mechanisms ensure users remain informed about exceedances or drops in levels, thereby boosting operational safety in humidity monitoring and temperature control environments.

- Seamless embedding into contemporary networks is a key strength of this device, aligned with the demands of Industry 4.0. It backs the MQTT standard, enabling easy inclusion in automation frameworks. Moreover, it provides immediate access to current measurements through HTTP or TCP connections, aiding the creation of custom solutions. Linking to the cloud platform allows global availability of data, which is especially beneficial for organizations with scattered locations. This extensive connectivity renders the tool indispensable in linked settings where instantaneous information and adaptability are required for effective IP sensor deployment.

- Data retention and worldwide accessibility are handled efficiently by the IP thermometer, featuring a local volatile storage that holds information for up to two days. For extended archiving, values can be stored in the cloud and retrieved from anywhere. This integration empowers teams to view progressions remotely, ideal for traveling groups or international firms. The recording interval can be adjusted to match specific needs. An internal clock, aligned with time servers, ensures accurate timestamps that simplify analysis in monitoring systems.

- This IP thermometer with Pt100 is designed for diverse usages. In data centers and cabinets, it tracks ambient conditions to avert overheating and prolong hardware lifespan. In workspaces, it aids in refining air conditioning, improving comfort while cutting energy bills. In factory settings, it suits process oversight where exact control is vital. Within sustainable computing initiatives, the device assists in boosting cooling efficiency by offering precise inputs for adjustments. The wireless capability permits adaptable placement without cabling hassles, broadening its application scope in remote monitoring scenarios.

- Compliance with standards and versatile power options are integral to this IP thermometer. It meets requirements for office and industrial deployments, boasting high immunity to interference per EN 61000-6-2 and low emissions according to EN 55032:2015 + A1 Class B, EN 61000-3-2, and EN 61000-3-3. These traits assure dependable operation even in challenging conditions. Power is supplied flexibly via Power-over-Ethernet, accommodating phantom powering over data pairs or via spare wire pairs. Alternatively, an external adapter can be employed, extending usability to sites lacking PoE setup.

- Please note: No power adapter is included in the package.

- Durability and dependability are hallmarks of this IP thermometer with Pt100, engineered for continuous operation and backed by a five-year warranty. Its sturdy construction and rail mounting option make it apt for industrial contexts. A battery-buffered internal clock maintains precise timing, enhanced by synchronization with time servers. These attributes highlight the device's longevity and trustworthiness under rigorous circumstances in environmental sensors applications.

- An essential instrument for oversight, this IP thermometer from the producer represents a state-of-the-art answer for meticulous environmental tracking across multiple situations. With its Pt100 probe, wireless linkage, and cloud connectivity, it delivers a pliable and solid solution for computing facilities, offices, and production sites. Backing for MQTT, alerts via ntfy.sh, and straightforward merging with IoT setups render it perfect for Industry 4.0 needs. Whether for streamlining energy use, logging values, or averting damages—this tool is vital for specialists.

To expand on the capabilities of IP thermometers in temperature monitoring systems, it's important to understand how these devices integrate with broader humidity monitoring frameworks. IP sensors allow for real-time data acquisition, which is critical in maintaining optimal conditions in sensitive environments. For instance, in server rooms, where even slight fluctuations can lead to significant downtime, employing an IP thermometer ensures that administrators receive immediate feedback on environmental changes. This proactive approach not only prevents potential disasters but also contributes to overall system efficiency. Furthermore, the use of WiFi temperature sensors extends the reach of monitoring beyond wired constraints, enabling deployment in remote or hard-to-access locations. Such flexibility is invaluable in industrial settings where machinery operates under varying conditions, requiring constant vigilance to maintain performance and safety standards.

Incorporating IoT temperature sensors into existing infrastructures enhances the scope of environmental monitoring systems. These sensors can communicate seamlessly with central hubs, aggregating data from multiple points to provide a comprehensive overview. This integration facilitates advanced analytics, where patterns in temperature and humidity can be analyzed to predict future trends or identify inefficiencies. For example, in agricultural applications, though not directly related to the core focus, the principles apply similarly in controlled environments like greenhouses or storage facilities. Back to the primary context, in data centers, the ability to set thresholds for alarms ensures that any deviation triggers an immediate response, whether through email, SMS, or app notifications. The reliability of Pt100 sensors in these setups cannot be overstated, as their precision directly impacts the accuracy of the entire monitoring chain.

The evolution of remote temperature monitors has brought about significant advancements in how we approach climate control. Modern devices support protocols like MQTT, which allow for efficient data transmission in low-bandwidth scenarios, making them ideal for large-scale deployments. Cloud-based monitoring further amplifies this by offering storage and access capabilities that transcend local limitations. Users can visualize data through dashboards, generate reports, and even automate responses based on predefined rules. In terms of server room monitoring, this means that IT teams can maintain oversight without being physically present, reducing response times and operational costs. The incorporation of data loggers ensures historical data is preserved, aiding in compliance with regulatory standards and facilitating audits. Overall, these systems represent a paradigm shift towards smarter, more responsive environmental management.

- Exploring the role of humidity sensors in conjunction with temperature monitoring reveals their importance in preventing issues like condensation or mold in enclosed spaces. By measuring relative humidity alongside temperature, these sensors provide a fuller picture of the environment, enabling more informed decision-making.

- Environmental monitoring systems often include features for power management, such as PoE, which simplifies installation by combining data and power over a single cable, reducing clutter and enhancing reliability in critical setups.

- Alarm systems integrated into IP thermometers can be customized to various sensitivity levels, ensuring that notifications are relevant and not overwhelming, thus maintaining user engagement and system effectiveness.

- Cloud integration allows for scalable solutions, where multiple devices can be managed from a single interface, streamlining operations for enterprises with extensive networks.

- The use of industrial temperature control mechanisms ensures that processes remain within safe parameters, preventing overheating or freezing that could compromise product quality or safety.

- Data logging capabilities enable retrospective analysis, which is crucial for troubleshooting and optimizing systems over time, providing insights that drive continuous improvement.

- In terms of IoT sensors, security features like encryption and secure authentication are paramount to protect sensitive data from unauthorized access, ensuring the integrity of the monitoring network.

- Remote monitoring extends to mobile applications, allowing users to check status on-the-go, which is particularly useful for field engineers or managers overseeing multiple sites.

- WiFi temperature sensors offer ease of connectivity, but it's essential to ensure network stability to avoid data loss, often achieved through redundant connections or failover mechanisms.

- Server room temperature monitoring requires sensors with high resolution to detect subtle changes that could indicate emerging problems, such as failing cooling units.

- IP sensors can be part of larger smart building systems, integrating with HVAC controls to automate adjustments based on real-time data, enhancing energy efficiency.

- Temperature monitoring systems in healthcare settings, for example, ensure that storage conditions for medications are maintained, preventing spoilage and ensuring efficacy.

- The adaptability of these devices to different power sources, including batteries or solar, makes them suitable for off-grid applications where traditional power is unavailable.

- Advanced analytics in cloud platforms can employ machine learning to predict anomalies, providing predictive maintenance capabilities that save costs in the long run.

- Finally, the combination of all these elements—IP thermometer, humidity monitoring, IoT integration—creates a robust framework for comprehensive environmental control, adaptable to future technological advancements.

Diving deeper into the technical aspects, the precision of Pt100 sensors stems from their resistance-temperature relationship, which is linear and highly reproducible, making them a standard in metrology. In IP thermometer applications, this translates to minimal calibration needs and long-term stability, reducing maintenance overheads. When combined with digital interfaces, these sensors can achieve resolutions down to 0.01 degrees Celsius, crucial for applications requiring fine-grained control. Moreover, in humidity monitoring, capacitive or resistive sensors are often paired, offering accuracy within 2-5% relative humidity, sufficient for most industrial needs. The synergy between temperature and humidity data allows for calculations like dew point, which is vital in preventing moisture-related issues in electronics or storage.

From a networking perspective, the adoption of MQTT in temperature monitoring systems exemplifies lightweight messaging protocols designed for constrained devices. This protocol's publish-subscribe model decouples senders and receivers, enhancing scalability in IoT ecosystems. For instance, an IP sensor can publish readings to a broker, from which multiple subscribers—like dashboards or alert systems—can consume data independently. This architecture supports real-time updates without polling, conserving bandwidth and power. In cloud integration, services like AWS IoT or Azure provide robust backends for data processing, storage, and visualization, allowing users to leverage big data tools for deeper insights.

The practical deployment of these systems involves careful consideration of placement and calibration. Sensors should be positioned away from heat sources or airflow obstructions to ensure representative measurements. Regular calibration against reference standards maintains accuracy over time. In server room scenarios, redundant sensors can provide failover, ensuring continuous monitoring. Power options like PoE not only simplify wiring but also enable centralized power management, useful in large installations. Overall, the holistic approach to designing these systems—encompassing hardware, software, and operational protocols—ensures they deliver value in enhancing reliability and efficiency.

- Considering the evolution of environmental sensors, from analog to digital, has enabled more sophisticated data handling, including wireless transmission and integration with mobile apps for user convenience.

- Alarm notifications can be tiered, with minor deviations triggering warnings and critical ones activating emergency protocols, allowing graduated responses.

- PoE enabled devices reduce installation costs by eliminating separate power lines, making them attractive for retrofitting existing buildings with modern monitoring capabilities.

- Data logging at variable intervals allows balancing between detail and storage efficiency, with higher frequencies for critical periods and lower for stable conditions.

- Industrial temperature control often involves PID algorithms in connected controllers, using sensor data to adjust heating or cooling elements dynamically.

- In remote monitoring, VPNs or secure tunnels protect data in transit, ensuring compliance with data protection regulations like GDPR.

- WiFi temperature sensors benefit from mesh networking in large areas, extending coverage without additional infrastructure.

- Server room monitoring extends beyond temperature to include air quality and particulate matter, providing a comprehensive health check for equipment.

- IP sensors with API access allow custom software development, tailoring the system to specific business needs.

- Temperature monitoring systems in logistics track cold chains, ensuring perishable goods remain within safe ranges during transport.

- The use of open-source platforms for cloud integration lowers barriers to entry, enabling small businesses to adopt advanced monitoring without high costs.

- Humidity sensors require periodic cleaning to prevent drift due to contaminants, maintaining accuracy in dusty or humid environments.

- IoT temperature sensors often include battery life indicators, alerting users to impending replacements to avoid downtime.

- Environmental monitoring systems can integrate with building management software, automating lighting and ventilation based on occupancy and conditions.

- Ultimately, the investment in quality IP thermometers and associated technologies pays off through reduced risks, optimized operations, and extended asset lifespans.

WLAN thermometer 1x Pt100